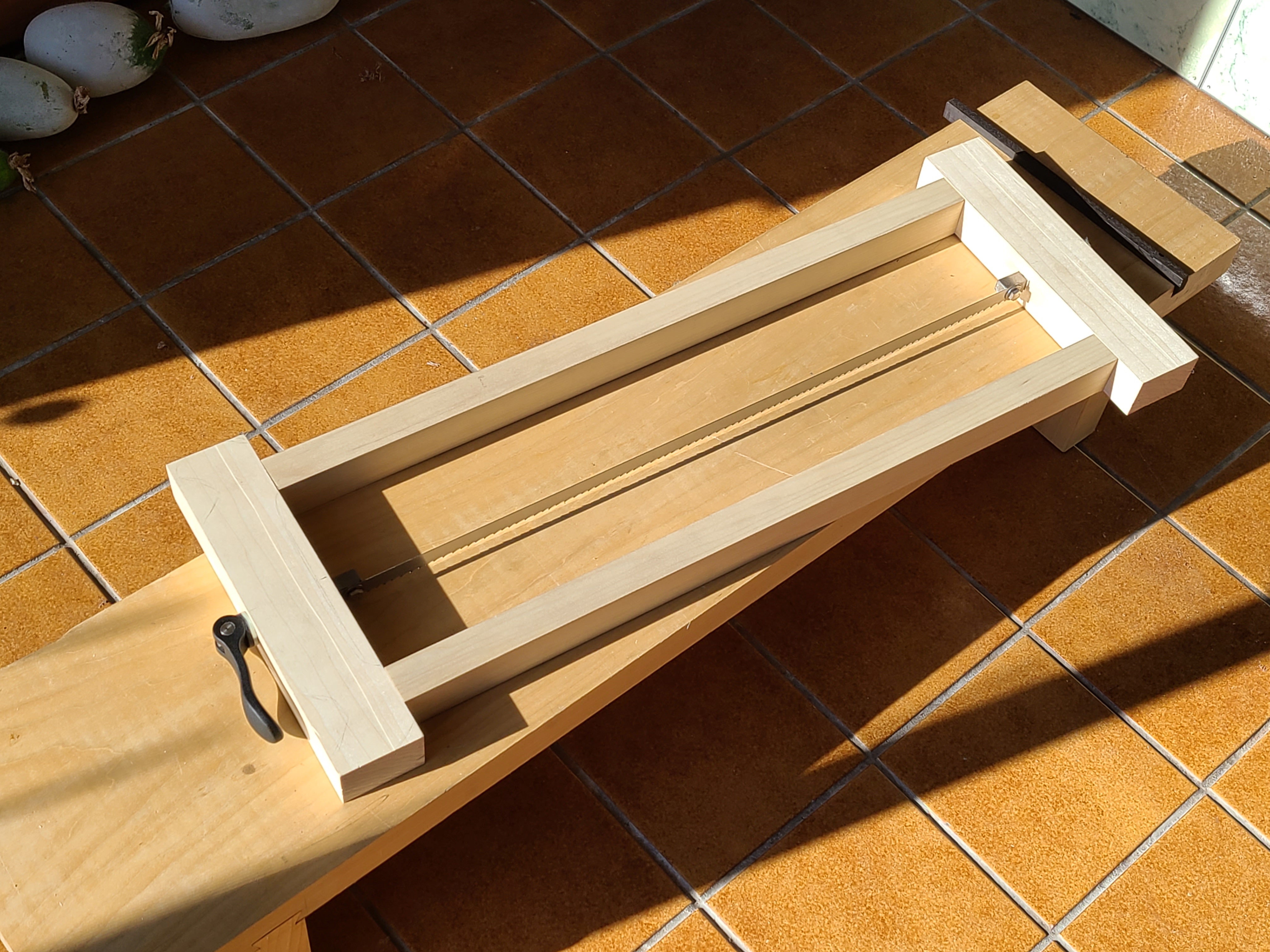

Bandsaw Blade Frame Saw

After a very bad experience trying to resaw an eight inch wide board with a ten inch ryoba, I needed something better. With no suitible location (or interest in spending much) for a bandsaw, I decided to try making a frame saw. Common wisdom is that a bandsaw blade is too narrow and will make a saw that is difficult to keep following the line. This is true, still this saw remains my primary tool for resawing and gets frequent use.

Mistakes and what I don’t like about the saw

- The blade is not centered in the frame, causing the saw to sit unbalanced.

- The blade is too short, only 25 inches long.

- Stretchers are thicker than needed.

What I like about the saw

- Narrow frame is easy to hold.

- Cam handle for tensioning the blade works well. It allows easy adjustment. Open the blade remains tight but not tensioned.

I have not been able to follow a cut without a starter kerf on each side of the board at least 2-3 teeth deep. Perhaps with more practice or care I could do it? In the mean time I am limited to cutting fairly short stock since it must fit within the saw to cut the kerf. I don’t have a kerfing plane. It works well enough; the projects I am doing with thin stock rarely need panels greater than 18 inches long.

Nearly completed saw. I gave it a go before deciding that the handles and edges really must be shaped better. They have been since knocked off with a rasp but not completed as fancy as traditional designs would indicate.

The blade is held to the square rod by a pair of spring washers (cone shaped). The idea is that the entire width of the blade is well secured.

Design Details

How strong does the saw frame and tensioning mechanism need to be? From Forrest “What is blade tension?”: “For carbon steel toothed blades (cutting blades) this is typically 15,000 to 25,000 PSI. … In general bandsaw blades are never tensioned past 35,000 psi.” The Wood Slicer blade is 0.022 by 0.625, giving a cross sectional area of 0.0138 square inches. Tensioning this blade to 25,000 PSI requires 345 pounds.

Kit frame saws use blades from 2” to 4” wide and 0.03 to 0.042” thick. A 3” x 0.042” blade tensioned to 25,000 PSi would require 3150 pounds! I would like to try a wider blade, but I guess that will require a better tensioning mechanism.

The right panel is straight off the saw. You can see the vertical line from the kerfing cut on the edge.

A sample of thin stock produced with this saw.